Printing process in the screen printing procedure

How does screen printing work?

Alongside serigraphy and textile screen printing screen printing falls under the so-called pressure printing processes. A squeegee is used to press the coloured ink through a fine-mesh sieve cloth with a template of the desired print image. At these points a photo-sensitive, waterproof layer is applied. The areas to be printed are open, since lighting was used to detach the layer. Tissue thickness and density of the stretched tissue combine to produce a definite ink film thickness, which can be reconstructed very accurately.

Graphic view screen printing process

1. The prepress stage involves creating a film that is black at the points to be printed.

2. Following stand mounting the film is copied onto the layered screen using UV light.

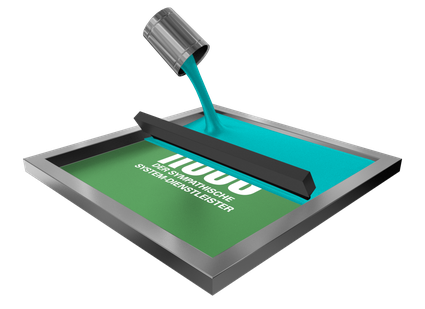

3. Initially the screen is built into the machine, then screen printing colour is added to the screen and spread evenly over the whole screen using the flood bar.

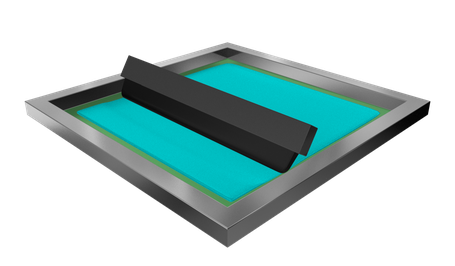

4. The print sheet is now positioned. With the aid of the print squeegee the paint is pressed through the open screen mesh and transferred to the print sheet.

PRINT RESULTS

Advantages of screen printing process

Wide selection of printing material

No other printing process is in a position to provide such an extensive range of printing material: paper, cardboard, packaging, virtually all plastics, metal, wood, glass etc. can all be printed by screen printing.

High colour layer thickness

The colour applied in screen printing is up to 5 times thicker than in other printing processes. The thickness of colour applied averages 7 μm and rises to 1 mm. For this reason this printing process is irreplaceable for a series of applications such as for finishing offset print media with varied effects and in the area of printed electronics.

Independence with misprints

The screen printing process facilitates overprint of special effects, conductive paste, fragrances, adhesives or pigments. The special screen printing colours possess high opacity, light fastness, good resistance to weathering and scratch resistance.

lc-buttons (direkt) - diesen Eintrag nicht löschen oder verschieben!