Flexible printed circuits

Flexible circuits for membrane keyboards

We develop and produce durable flexible printed circuits for your input solutions and membrane keyboards. As an alternative to rigid printed circuit boards, flexible circuits have been used for a long time in technical system controls and operating elements. In the meantime, they are also finding their way into traditional household electrical appliances.

How are flexible electronic circuits manufactured?

The screen printing process enables the production of printed electronics on flexible, thin and lightweight materials. By manufacturing through screen printing, flexible circuits achieve excellent properties at low material and production costs compared to rigid circuit boards. A polyester film is usually used as the base material. The conductor tracks are printed with conductive inks and then coated with abrasion-resistant graphite, which assures a long service life for the circuit foil.

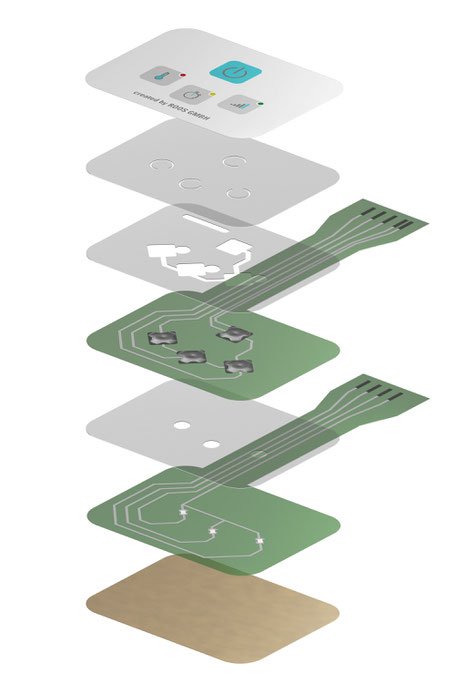

Flexible printed circuit in a membrane keypad

Front membrane

- resistant to most chemicals

- individually configurable

Retaining membrane

- fixes the installed metal snap domes

Spacer foil for switching level

- self-adhesive spacer

- positioning of the snap domes

Switching layer

- printed electronic circuit

- equipped with metal snap domes

Spacer foil for LED level

- self-adhesive spacer

- insulation of upper and lower switching foils

LED layer

- printed electronic circuit

- equipped with single and multicolour LEDs

Base adhesive

- lower adhesive layer for mounting the membrane keypad

Together, we develop the optimal circuit design tailored to your specific application area.

lc-buttons (direkt) - diesen Eintrag nicht löschen oder verschieben!