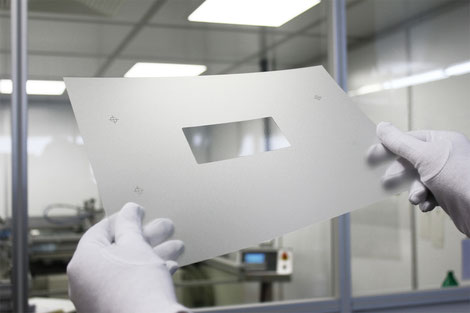

Screen printing under clean room conditions

Alongside technical requirements such as the functionality, resilience and service life of membrane keypads, considerable value is placed on a decorative and individual design for the front membrane. From a technical printing point of view, screen printing offers unique opportunities in this area. We use special screen printing colours, textured paints, coloured glazes, fade effects and clear coats in the manufacture of design membranes. To make a display visible behind a milky, matt front membrane, for example, the front membrane is partially printed with a special UV clear coat. The UV coating changes the structure of the membrane. As a result, a crystal clear, highly transparent window is created. Glazes and screen printing colours are then applied to the back of the membrane, resulting in a hardwearing smear and scratch-proof design membrane.

Fine dust in the ambient air presents a challenge when manufacturing front membranes using glazes and special lacquers because the dust can significantly affect the production quality. In order to keep the chance of possible problems appearing as low as possible, we print the design membranes under dust-free conditions in a clean room in our company. Dust exposure is reduced in the clean room during the work processes through the use of powerful filters and overpressure.

Thanks to the modern equipment in our production facilities, we are able to produce front membranes and membrane keypads of the highest quality and, most importantly, to do this consistently. We are right at your side to provide help and advice with your project planning. We are happy to personally advise you and work with you to find the optimal solution for your project.

16.01.14

lc-buttons (direkt) - diesen Eintrag nicht löschen oder verschieben!