Printed flexible circuits in electrical connection technology

The application of flexible printed switching foil opens up a wide range of innovative applications. The range of applications extends from high-tech devices to input systems from medical technology and industry to end-user devices.

The screen-printed electrically conductive foil sector is continuing to grow. This is due to both the unique properties of the flexible silver circuits and the possible further development in terms of the base material and the potential future applications.

Advantages of flexible printed circuits

Flexible printed circuits are conductive, lightweight, thin and cost-effective, and offer a variety of decisive advantages in a wide range of applications. Their lightness and minimal installation depth have a positive effect on the dimensions and weight of the end device. However, the most significant advantage of printed silver circuits compared to flexible etched circuit boards arises from the lower production and material costs. Developers can therefore now use flexible circuits in applications that were previously not cost-effective.

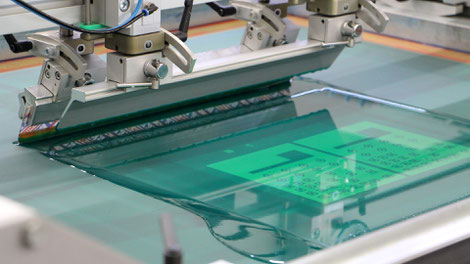

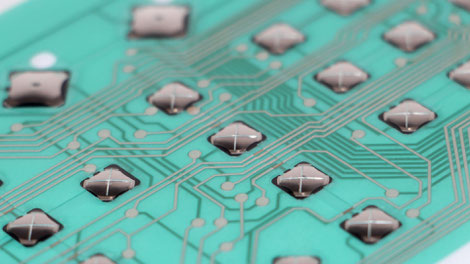

Production of flexible circuits based on silver conduction technology

The screen printing process enables the production of printed electronic circuits on flexible, thin and lightweight materials. The base material used is generally a polyester foil. The conductive tracks are applied with conductive silver using screen printing and then overprinted with an insulating layer to protect against corrosion. The contact points of the silver in the snap disc area and the connection point are coated with abrasion-resistant graphite to ensure a long service life of the switching foil. This is a very economical manufacturing process, as minimal waste is produced and no waste water treatment is required.

Membrane keypads with one and two switching level(s)

The advantage of using flexible circuits is primarily in the slim design. The membrane keypad may be from approx. 0.65 to approx. 1.5 mm high, depending on the design. A membrane keypad generally has a switching level (single-layer technology) on which both the snap dials and LEDs can be mounted. The LEDs can also be mounted on a second switching level (two-layer technology), depending on the complexity of the switching layout and the height of the component.

We manufacture durable and flexible printed circuits for your input solutions and membrane keyboards. We develop the optimal circuit design with you which will be designed to meet your specific application.

10.10.22

lc-buttons (direkt) - diesen Eintrag nicht löschen oder verschieben!